离心机主要应用于无机化工、有机化工、石油、制药及药品中间体、化学肥料、农药、染料、食品及添加剂等行业。通过强大的过滤压力--离心力,实现固液混合物的分离,同时可实现对分离产品的提纯(洗涤),因此,在诸多行业中得到了广泛的应用。

离心机适用性选择因素:

1)所分离的类型:液、固(介质腐蚀特性、防爆特性)

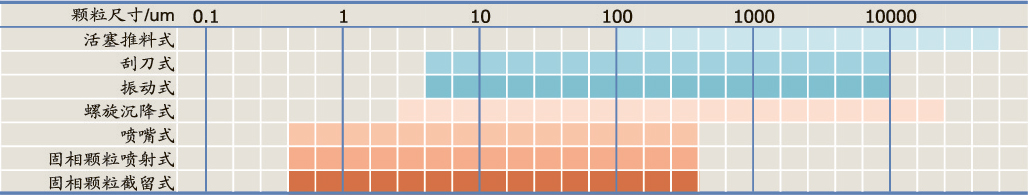

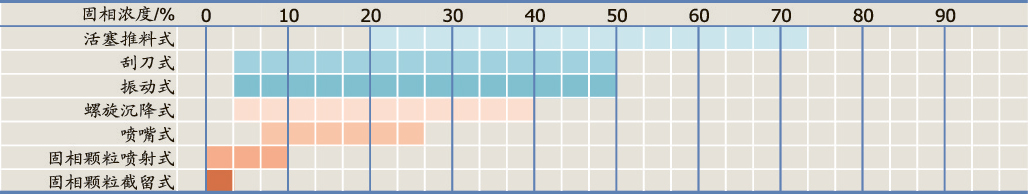

2)颗粒尺寸(粒径分布)、形状和密度

3)固相密度、料液的相对密度

4)沉降速度

5)流量

6)粘度

7)温度

8)PH值

9)产量

10)洗涤要求

11)GMP要求

...

固相颗粒大小、沉降速度和混合物浓度是主要的适用性衡量指标。除了上述的物料理化特性,还有诸如洗涤要求、液相含固率指标、滤饼含湿率指标等也是在选择应用时需要考虑的因素。

在选择分离工艺时,首先是从过滤、沉降或沉降+过滤方式中选择最适宜的技术。通常,沉降方法比过滤方法更为经济,特别是那些涉及大处理量、连续液体流的情形,沉降分离更为适宜。

Selection technologyof centrifuge

The centrifuge is mainly applied in field of nonorganic chemical, organic chemical, petroleum,pharmaceutical and intermediates, chemical fertilizer, farm chemical,dye, food and additives. With its centrifugal force, the powerful filtering pressure, the centrifuge is applicable for separation of solid/liquid mixture and purifying(rinsing)products out of the separation process and therefore widely applied in many industries.

Whether a centrifuge is applicable is determined by following factors:

1) Type of separation to be undertaken, liquid or solid(medium corrosive or explosion-proof?)

2) Size, shape and density of particles(size distribution)

3) Density of the solid content and relative density of the liquid content

4) Sedimentation rate

5) Sedimentation rate

6) Dynamic viscosity

7) Temperature

8) PH value

9) Throughput

10) Washing requirement

11) GMP requirement

...

Among which,size of solid particle,sedimentation rate and concentration of the mixture are three major index for determining applicability/serviceability of the unit.In addition to physical and chemical properties abovementioned,factors/index including washing requirement, solid content rate of the Iiquid phase, moisture content of the filtering cake and other factors also need to be considered while determining application/serviceability of the unit.

To define a most applicable separation process, the most suitable technoIogy to be applied shall be selected from three options, i.e.filtration, sedimentation or sedimentation plus filtration. Sedimentation option is more economic than the filtration option and it’s especially suitable in case of bulk amount of treatment and continuous flow of liquid.

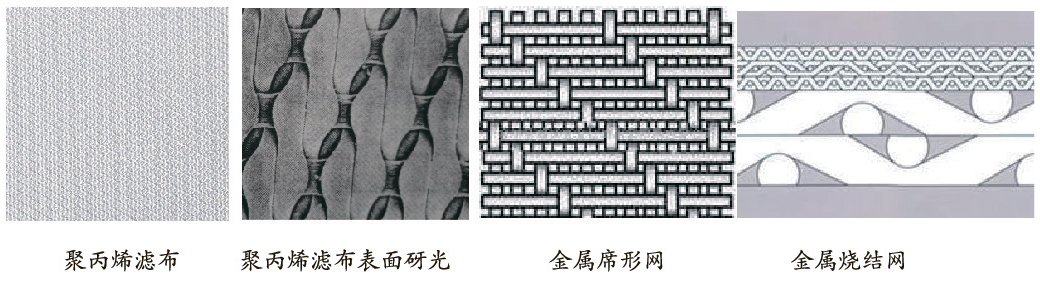

滤布选用

过滤过程中,由其表面或内部留住固体粒子的任何有渗透性的材料,称为过滤介质。过滤介质对过滤的效率、有效性往往起着决定性的作用。

过滤介质的主要作用是用最少的能量消耗将固体微粒从流动的液体中分离出来。

成功的过滤过程很大程度上取决于选择合适的过滤介质。通过研究与经验积累,在过滤介质的性能和选择方面有大量的技术信息可以参考,但过滤介质的选择还是在依靠对固液混合物的一些实验来选择,这些实验操作要非常仔细,实验工艺中很小的变化可能对结果产生很大的影响。

由于过滤介质的多样性造成选择过滤介质的工作很困难,仅依靠粒径测定和分布很难确定哪一种过滤介质最适合该分离操作。颗粒浓度和形状的改变也会给实际应用带来困难。

聚合材料制造的编织滤布和非编织建布:聚丙烯、聚乙烯、聚醋、聚酰胺、聚氯乙烯等。

单丝双层复合滤布:过滤介质是双面的,缎纹织法织出用于过滤的光滑表面,表面可经砑光处理得到进一步改善,较粗的单丝编织的下层有较好的强度起到支撑的作用并有助于排液,微粒在穿透过滤面后不会被滤布截留而是顺着支撑层内部的漏斗状孔道流出,而不至于卡在滤布中形成堵塞,也有助于滤布再生。

对于大颗粒固相,可选用金属烧结网或席形网作为过滤介质,以达到更高的过滤效率。

Selection of filtering

Filtration medium, which could be any permeable material that retains solid particle on its surface or inside of it in filtration process, determines effectiveness and validity of filtration process.

Main function of the filtration medium is to separate the solid particles out from the flowing Iiquid by consuming minimum energy.

Effective filtration, to a Iarge extent,depends on proper selection of applicable filtration medium, the customer may refer to those technical specification and information as results of research efforts and experience of the industry concerning performance and selection of filtration medium, however, to select the filtration medium, relevant experiments and tests shall be conducted to the solid and liquid mixture to be separated extremely carefully as a tiny change in process of experiments/tests might bring major impact to the results.

Diversity of the fiItration medium makes it a hard job to select the proper applicable one, you can hardly define which filtration medium is the most applicable for the specific separation operation simply by referring to its particle size and size distribution, in fact, change of partiele coneentration and shapes will make your decision of filtration medium harder.

Woven filter cloth and non一woven filter cloth made of polymeric material: Polypropylene,polyethylene, polyester, polyamide, polyvinyl chloride and others.

Single wire double-layer composite filter eloth:It’s a double-layer filtering medium, with satin weave texture on smooth surface of the top layer,such smooth surface may bo subject to matting treatment for improvement. The bottom Iayer is made of single wire woven cloth of higher strength which is supportive and helpful for discharging. Particles penetrating or passing through the top layer would not be retained there resulting in clogging, instead, it will flow down along the funnel in between the top Iayer and bottom supportive layer, which is good for regeneration of filtering cloth.

Metal net or mat sheet could be selected as filtering medium for large particle solid to achieve higher filtering efficiency.